Italy is not the only place where pasta is not only food but culture, comfort, and craftsmanship. But handmade tortellini is time-consuming and needs patience and practice to make. That is what the tortellinatrice alters. This intricate pasta maker remembers tradition, but, at the same time, helps to speed up the process, wrapping the past in every closed packet. Whether it is your home kitchen satisfying a Sunday craving, or a professional dining room keeping up a steady stream of plates without having to change anything about your quantity or quality, consistency and quality become pain-free.

It rerolls, cuts, fills, forms, and seals-and in minutes we are presented with the beautiful symmetrical tortellini. What you fill it with is still yours: the dough, the stuffing, the taste. The device copes with choreography. The tortellinatrice has adjustable settings in terms of thickness and size, therefore it is suitable for both old and new recipes.

It opens up innovation with no bottlenecks- spinach dough, pumpkin fillings, truffle butter finishes. It, above all, saves what is worthy of being saved, the bite, the smell, the smile at the table. And there is the rendezvous of tradition and technology, and dinner is served.

What Is a Tortellinatrice?

Tortellinatrice is a specialized pasta maker that machine-unites the laborious process of manufacturing tortellini. It automates the process of rolling, portioning, sealing, and cutting that would otherwise require hand folding, generating consistent results at speed. Models vary in size to include small countertop models suitable for the home enthusiast, to larger, continuous-feed systems used in restaurants and pasta labs.

Perfection in a tortellinatrice is the balance: respecting the iconic shape of the ring pattern and the great seal, and diminishing the hours of manual work. You make the dough and fillings; the machine ensures there is uniform reproduction. Authenticity remains, but inefficiency leaves- so more plates get to the table, just perfectly.

1. Why the Name Matters

The term tortellinatrice means “tortellini maker,” signaling a single-minded purpose: excellence in stuffed pasta. Unlike generic rollers, it’s engineered to protect delicate fillings, align edges, and press a reliable seal. That name conveys trust to chefs and clarity to buyers. If tortellini is your signature, a tortellinatrice is the focused tool that keeps standards high during rushes. It’s not just equipment; it’s your partner in consistency, safeguarding texture, shape, and the joyful snap of perfectly cooked pasta every service.

2. Core Job of the Machine

A tortellinatrice is used to turn her pre-made dough and filling into completed tortellini with precision repeatability. It cuts food items and pasta to be cooked evenly, lays pasta sheets, and seals edges to ensure that it does not leak water when it is boiling. The accuracy guards the taste and improves the presentation. Uniform size also means the tortellinatrice guarantees that cooking times become even, thus a full pot will finish at the same time. That reliability saves on waste, accelerates service, and improves customer satisfaction. Whether it’s twenty plates or two hundred plates, the core task is still the same: near-perfect bites, every batch.

3. Who Uses a Tortellinatrice?

The tortellinatrice serves enthusiastic home cooks, boutique trattorie, busy hotel kitchens, and artisanal pasta labs. Families love it for weekend feasts; caterers rely on it for volume; chefs value it for consistency across shifts. Culinary schools use it to teach dough science while producing practice-ready batches. Food entrepreneurs adopt it to scale without diluting quality. Wherever tortellini appears regularly—menus, meal kits, markets—the tortellinatrice becomes the quiet engine that keeps tradition alive while meeting modern expectations for speed and precision.

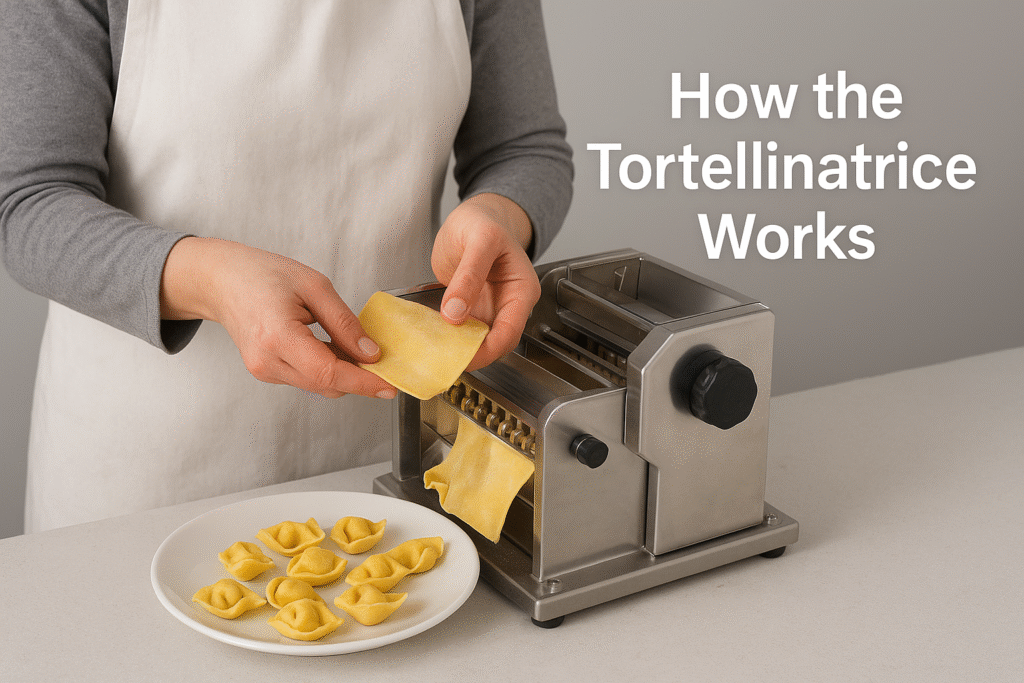

How the Tortellinatrice Works

A tortellinatrice acts in a feminine order. Dough is put into the rollers so that it has the same thickness. A filled system deposits measured filling. Guides wrap the pasta around the filling, molds cool the characteristic bend, and pressure points make a seal on the edge. The n cutters cut each tortellino.

Setting manipulates the thickness of the sheet, filling weight, t, and piece size, and some models have interchangeable molds. The score: the same, tightly stuffed tortellini, meant to be dried or cooked at once. The godlike process seems supernatural quality–your tastings, enhanced by industrial ballet–as you provide the artisanal feel, efficiency in the supply.

1. Dough Pathway and Rollers

In a tortellini maker, the roller does make a difference. They establish thickness, chew influence, and establish translucency. Too thin, seals do not hold up; too thick, texture doesn’t stand up. Good machines run on reliable, stainless parts and tight tolerances to keep the thickness the same throughout long production runs. That consistency allows for consistent cooking times and fewer rejected merchandise. For chefs, the roller pathway is like a metronome—it’s steady, it’s consistent, and it’s repeatable. Ping it once, try 1 piece, and let the line speak. The tortellinatrice captures muscle memory as machine memory, keeping your perfect bite.

2. Filling, Portioning, and Sealing

Great tortellini begins with accurate filling. The tortellinatrice meters portions to avoid explosive bursts or hollow centers. It guides dough over the filling, aligns edges, and applies sealing pressure exactly where needed. That seal is crucial: it protects flavor, prevents leaks, and keeps the pasta buoyant. Better sealing also means cleaner water, fewer floaters, and a glossy, intact surface. With portioning dialed in, every piece tastes balanced—dough, filling, and sauce in harmony. Precision here saves money, time, and reputation.

3. Cutting, Ejection, and Flow

A tortellinatrice removes the pieces by use of cutters after sealing, after which she ejects them smoothly to be placed in trays or floured pans. No raggedness to snag while cooking as a result of clean cuts. The last phase of the flow is important: delicate treatment maintains forms intact, so that they do not get squeezed out or crushed. Large numbers of tortellini are staged in sheet pans in the kitchen to chill or dry. Such a body makes service easy and safeguards uniformity. The machine is not making tortellini per se; it forms a replicable assembly line, coordinated prep, par-cook, and pickup at a placid pace.

Types of Tortellinatrice Machines

Tortellini aren’t the same. The manual crank types are applicable in small batches and controlled by touch. Semi-automatic units provide metered filling as well as hand adjustments. Fully automatic systems are able to provide both the highest throughput and programmable settings, as well as continuous feeds.

Home machines stress low footprints and simple clean-ups. Industrial machines also give priority to stainless frames, industrial motors, and swap-in molds. It is chosen based on volume, the capability of employees, and the menu concept. Say you have tortellini as your staple, invest in capacity; say it is a rotating special, go with flexibility. The correct appliance enhances the beat of your kitchen.

1. Manual vs. Automatic

Manual tortellinatrice models appeal to craftspeople who like to use their hands and their eyes to make little corrections to the dough in response to touch. They are cheap and mobile. The focus of automatic machines is the output: well-portioned, regular seals, and fewer fatigues. Semi-automatic is in the middle, which is a good option in the case of the demand for boutique restaurants that produce batches every day.

2. Home, Pro, and Lab Builds

A home tortellinatrice would prefer to be simple: fast to put together, straightforward levers, and cleanable in the dishwasher. Pro units are also heavy, quiet when running, and constructed to work on a 2-shift system. Factories and pasta labs incorporate conveyers, hoppers with bigger capacity, and in-line cooling racks. Think in workflows: flour storage, staging for the fillings, pans of the finished piece, and the lanes to the cookline. Make the environment consistent.

3. Molds, Sizes, and Upgrades

Exchangable molds enable a tortellinatrice to change its character— smaller aperitivo snack, classic rings, or larger-sized generous stuffed parcels. Upgrades include finer filling pumps for soft ricotta mixes, non-stick contact surfaces, and variable speed drives for delicate doughs. Certain machines are complemented with ravioli or cappelleti attachments, adding more menu options without adding instructional time.

Benefits That Win Every Service

A tortellinatrice provides speed, consistency, and controls the cost. Even cooking, beautiful presentation can be seen in a standardized size. Filling with controlling meters minimises waste; competent seals minimise losses. Work evolves, away from the rote-fold, to a more imaginative prep-dealing with better doughs, jauntier fillings, creamier sauces.

The differences are experienced by the guests: tender bite, balanced flavor, and piping-hot plates on time. On the owner’s side, the numbers look better than ever: increased throughput, reduced fatigue, fewer remakes. To a cook, morale is increased as drudgery is turned to craft. It is a payback machine in terms of both previously saved minutes and happy repeat customers.

1. Speed and Throughput

I ten-minute placements now become two, thanks to the tortellinatrice. That multiplier differs on weekends, banquets, and holidays. You make more plates, none of which fall in quality. Faster batches also equate to more fresh service—less holding, better sauce, brighter herb. Line cooks sleep a little better; chefs can taste and teach. Throughput isn’t just faster, it’s peaceful. Guest detects that flow on warm, careful plates and assured service. When speed backs craft satisfaction is building, and reviews follow. Kitchen stops running after; it drives.

2. Consistency and Quality

Hospitality is consistency. A tortellinatrice locks shape, size, and seal in, thus ensuring each dinner guest experiences the desired crunch. Even pieces cook evenly, taking on the same sauce. That predictability allows chefs to season batch to batch accurately. It also wastes less: fewer broken pockets, clouded water, or rings. There is also a better presentation, sleek, clean tortellini, that photographs well. Regularity does not wash character away; it preserves i,t and it makes the first plate of pasta as well as the final one have the identical bite.

3. Cost, Waste, and Labor

The tortellinatrice wastes less with a precise fill and a tight seal. Less rework means more profit. Labor changes from tedious to high-value addition: emulsifying sauces, finishing with butter and stocks, plating with a conscience. Fatigue of the staff decreases; training improves. Week after week, those small wins build up— cleaner books, content teams, steadier margins. You’re not cheating, you’re streamlining. The consequence is a kitchen that invests in time where visitors can taste it.

Choosing the Right Tortellinatrice

Starting with volume plates per service, services per week. Then evaluate the style of dough, fillings, and size wanted. What you should find is a tortellinatrice who can match your recipes, not be something you have to compromise with. Pay great attention to stainless construction, scalable disassembly, and availability of spare elements.

Measure hopper capacity, cleaning time, and noise. In case you are contemplating diversification, look out and check the availability of molds. Test your dough a little-is the seal sticking? In a matter of a bit, does it feel right? Buy the workflow that you desire in six months, and not in the present rush.

1. Capacity and Settings

There is the law of sanity, which is ruled by capacity. An adjustable-turnover, portion-controlled spindle tortellinatrice responds to the weekday trickle or weekend storm. Knobs of thickness and filling knobs are used to adjust chew; soft fills need protection. Prefer machines that retain settings-it should be the same on both shifts. When you batch, make sure that ejection falls clean on pans. Bright dials now avoid the next day headaches, and allow you to scale without having to rewrite your playbook every service.

2. Materials and Hygiene

Choose a tortellinatrice that is made of stainless steel food-grade material and possesses clean seams, and has minimal crevices. Cleaning between the fillings will be quickened, and mixed flavors will not be exhausted without the use of tools. Tomato and wine reductions are characterized by acids that are insensible on enduring surfaces. Good hygiene lacks glamour of any kind, but it is there where reputations are won or lost. Where everything is washable in a dishwasher, or can receive rinses of hot water, night-side doesn’t matter, and mornings are fresh.

3. Support and Spares

Great machines fail gracefully. Pick a tortellinatrice with local service partners, clear manuals, and readily available spare parts—belts, gaskets, blades. Downtime during holidays is brutal; proactive support keeps you cooking. Ask vendors for training sessions and maintenance schedules. When the relationship includes service, not just shipping, your team gains confidence—and your tortellini keep flowing, no matter who’s on the shift.

Step-by-Step: Using a Tortellinatrice

Make velvet dough with very good gluten formation and a smooth surface. Freeze fills to keep a shape. Adjust tortellinatrice thickness, test a few, adjust portioning, and run a small amount. Inspection of seals, bite, and cooking times. Lightly sand trays, lay pieces in single layers, and refrigerate (if holding). Cook in salted water till they are quite tender; finish in butter, stock, or light cream, in order to glaze them. Plate quickly. Your friend is repeatability: lock steps, log setting,g, and win service.

1 . Dough and Filling Prep

The tortellinatrice rewards good prep. Use fine “00” flour, fresh eggs, and proper rest to relax gluten. Keep fillings smooth—no large chunks to puncture seals. Season boldly; fillings taste milder after boiling. Chilled, pipeable texture improves portioning. Treat prep like mise en place for flavor and performance: when inputs shine, the machine sings.

2. Calibration and First Batch

Calibrate the tortellinatrice before starting on full production. Conduct 5 trial pieces, adjust thickness, portioning, and pressure. Boil and test. When the bite is too hard, thin the sheet; when the fillings leak, up the sealing pressure or reduce the moisture. Document settings. Such notes reduce guessing to a process- your secret sauce to consistent repeat wins, shift after shift.

3. Cooking and Finishing

Bring plenty of salted water to a moderate boil, and into it, plunge cook tortellini. Glaze by skimming in a pan with butter, stock, or slightly thickened cream. Wet kiss, not drowned in sauce. Add herbs, Parmigiano, and cracked pepper. Put at once in warm dishes. The objective is purity: sensitive skin, delectable paste, and an iridescent Supreme that ensures gratification in the very first bite.

Benefits of Using the Tortellinatrice in Italian Kitchens

- Speeds up the pasta-making process significantly.

- Ensures consistent shape and size for each tortellini.

- Reduces manual labor, saving energy for chefs.

- Maintains authentic Italian pasta quality.

- Allows for large batch production without compromising taste.

- Easy to operate, even for beginners.

- Minimizes dough wastage during production.

- Offers adjustable settings for different pasta fillings.

- Durable design ensures long-term use.

- Helps restaurants and home cooks meet high demand efficiently.

Conclusion

The Tortellinatrice is more than just a kitchen appliance—it’s a symbol of how tradition and technology can work hand in hand to bring the best of Italian cuisine to every home. By automating the delicate process of crafting perfect tortellini, it preserves the authenticity of this beloved pasta while making it accessible to chefs of all skill levels. Whether you’re running a bustling Italian restaurant or preparing a family meal on a Sunday afternoon, the Tortellinatrice saves time without compromising quality.

This innovative machine ensures consistency in every piece, helping maintain the signature taste and texture that make tortellini a timeless favorite. It also allows for endless creativity—experimenting with new fillings, flavors, and dough types becomes effortless. For many, it’s not just a tool but an inspiration to explore more of Italy’s rich culinary heritage.

In a world where convenience often overshadows craftsmanship, the Tortellinatrice strikes the perfect balance, keeping the soul of Italian pasta-making alive while embracing modern efficiency. It’s a must-have for anyone passionate about food, culture, and the joy of sharing authentic meals. With the Tortellinatrice, the heart of Italy can truly be served fresh at your table every single day.