Introduction

An EDM machine, also known as an EDM spark erosion machine, is a precision tool in modern manufacturing. It performs EDM machining—a process using electrical sparks to shape materials. This introduction gives you a simple, clear view of how EDM machines work and why they matter. We’ll break down types like wire EDM machine and explore how these tools deliver unmatched precision.

What Is an EDM Machine?

An EDM machine, short for electrical discharge machining, shapes hard metals using electric sparks rather than cutting tools. The machine has two electrodes, separated by dielectric fluid. Sparks jump the gap, removing material with tiny craters.

This process works especially well on very hard metals like titanium, ceramics, and tool steels. The spark, fluid, and tool never touch physically—this avoids damage and distortion.

Why Use an EDM Spark Erosion Machine?

EDM spark erosion machines offer key advantages:

- They shape extremely hard metals that regular tools can’t touch.

- They handle complex shapes with tight tolerances and fine finishes.

- They protect delicate parts—no physical contact means no damage.

- They produce excellent surface quality with minimal post-processing.

Types of EDM Machining

EDM machines come in three main types. Let’s simplify how each works:

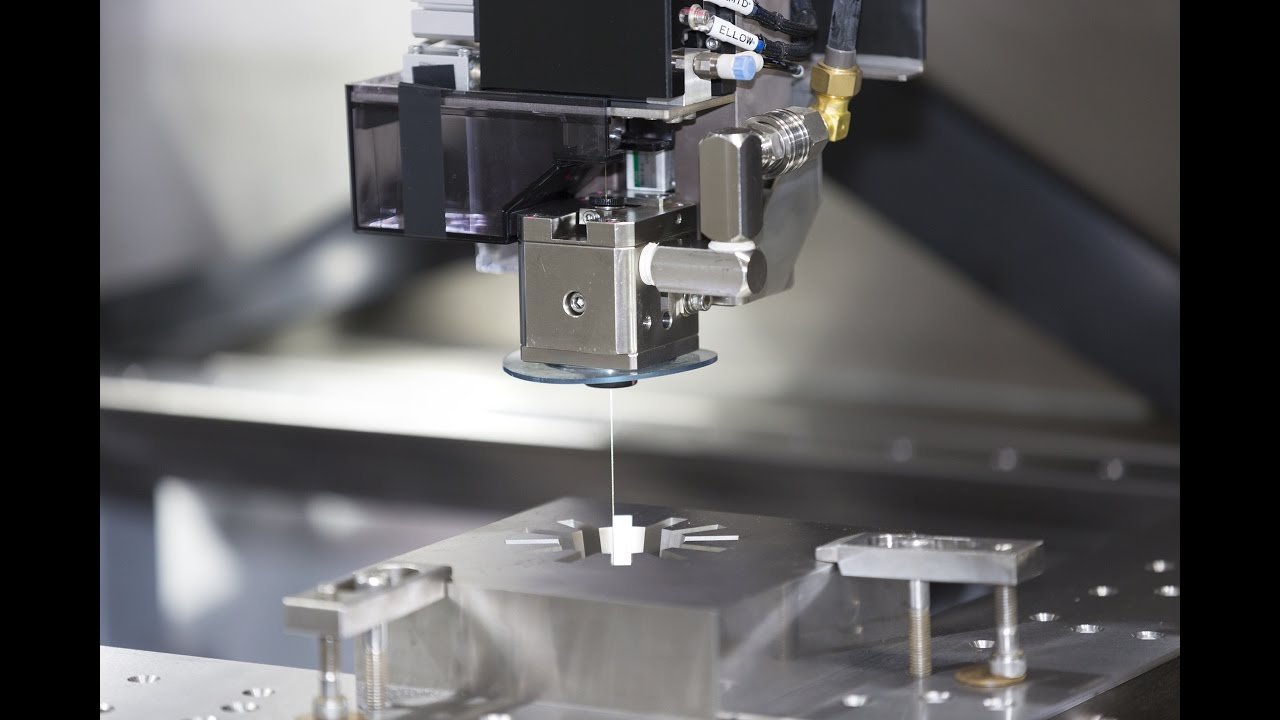

1. Wire EDM Machine

Wire EDM, also called wire-cut EDM, uses a thin conductive wire—usually brass—as the electrode. It moves through the workpiece, submerged in dielectric fluid. Sparks erode material along the path.

This method cuts intricate shapes with precision. It supports complex profiles and tight inside corners, even in thick metal plates.

2. Sinker (or Ram) EDM Machine

In sinker EDM, also known as ram or cavity EDM, a shaped electrode is plunged into the workpiece to erode a cavity. The electrode matches the desired result.

This method shines in mold and die work where detailed 3D cavities are needed.

3. Hole Drilling EDM

Hole drilling EDM uses a rotating tube as the electrode to drill deep, narrow holes. It pumps dielectric fluid through the tube for cooling and flushing debris.

This type is ideal for aerospace, turbines, and tiny fuel-system orifices.

How Does EDM Machining Work?

EDM relies on electrical sparks to precisely remove bits of metal. Here’s how:

- Setup: Tool and workpiece connect to a power source and sit in dielectric fluid.

- Spark gap: A tiny gap forms between electrode and workpiece. Electric field causes dielectric breakdown.

- Material removal: Sparks vaporize or melt tiny spots of metal—each forms a crater.

- Debris removal: Fluid flushes out eroded particles.

- Repeat: The cycle repeats thousands of times to reach full shape.

A Reddit summary puts it plainly:

“They basically run an electric current through either a wire or a die… electricity vaporizes the metal on a granular level.”

Materials & Applications

1. Materials

EDM machines only work on electrically conductive materials. These include:

- Hardened steels

- Titanium and superalloys (like Inconel)

- Carbides

- Pre-hardened or heat-treated metals

2. Applications

EDM shines in industries where precision meets complexity:

- Mold and die making

- Aerospace (e.g., turbine cooling holes)

- Automotive (prototypes, tooling)

- Electronics and medical devices

Advantages and Disadvantages

1. Advantages

- Precision: Achieves micron-level accuracy.

- No physical cutting forces: Ideal for delicate or very hard materials.

- Complex shapes: Can create cavities and tight corners.

- Good surface finish: Reduces post-machining work.

2. Disadvantages

- Slow process: Lower removal rate than conventional machining.

- High power usage: Can be expensive to run.

- Electrode wear: Especially in sinker EDM, electrode shape changes over time.

- Safety: Dielectric fluids like oil may pose fire risks.

Design Tips & Technical Notes

For top results with EDM:

- Use proper wire diameter relative to corner radii. Wire must be less than twice the minimum internal radius.

- Use low energy pulses for fine finishes. High energy heaps up debris.

- Plan electrode wear compensation—especially for sinker EDM.

Trends & Innovations

Leading EDM manufacturers push innovation. For example, Makino introduced:

- Drop-tank wire EDM (1994)

- High-quality surface finish tech (HQSF, 1996)

- Micro EDM ram machines (2003)

- Fast wire EDM and surface wizard improvements.

These changes boost speed, surface quality, and automation.

Conclusion

An EDM machine—whether EDM spark erosion machine, wire EDM machine, or EDM drilling tool—delivers unmatched precision. It excels on complex, hard, or delicate materials, delivering smooth surfaces and intricate shapes. Although slower and less energy-efficient than conventional machining, EDM’s unique strengths make it indispensable in tool-making, aerospace, medical devices, and more.

With continued innovation in control systems and automation, EDM machines remain a cornerstone of modern precision manufacturing.

FAQs

1. What is an EDM machine?

An EDM machine uses electric sparks to remove material from conductive metals. It shapes parts without physical cutting, ideal for hard or complex materials.

2. How is wire EDM different from sinker EDM?

- Wire EDM: Uses a wire electrode that moves through the workpiece. It cuts intricate 2D shapes with precision.

- Sinker (ram) EDM: Uses a pre-shaped electrode to create 3D cavities by plunging into the workpiece.

3. Can EDM machine tough metals like titanium?

Yes—EDM works well on hard or refractory metals such as titanium, tool steel, and carbides that resist traditional machining.

4. What are the main disadvantages of using EDM?

EDM is relatively slow, uses more power, can wear out electrodes, and needs careful handling of dielectric fluids.

5. Where is EDM commonly used?

EDM finds use in mold and die making, aerospace (like turbine holes), automotive toolmaking, electronics, and medical device manufacturing.